We are able to supply bespoke Tool Kits for general maintenance on aircraft, ships etc.

RATS

We have for many years been supplying RATS kits to various ship and boat manufactures. We have been involved in refits on Type 45 Destroyers, Type 23 Frigates, Patrol and Mine Hunters etc. The cases are manufactured from G.R.P and the tools are set in CNC routed foam panels, making an excellent tool control system.These kits are placed in all sections of the ship for general maintenance. We currently hold in excess of 3000 drawings showing the contents of each kit. Electrical, Engine maintenance, Radar etc.

We also hold muster books for many ships which contain information showing the kits required in each ship.

TOOL CONTROL SYSTEMS

A tool control system is, simply , a method and a container, designed to and hold a specific tooling requirement for designated work,for example on ships, aircraft, vehicles ,in industrial environments.

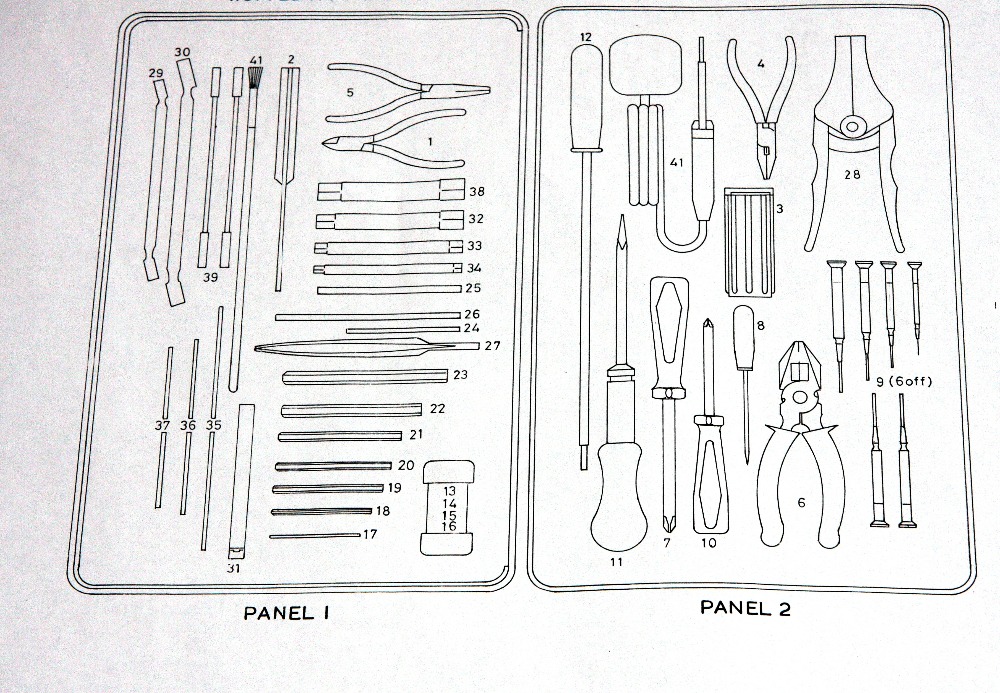

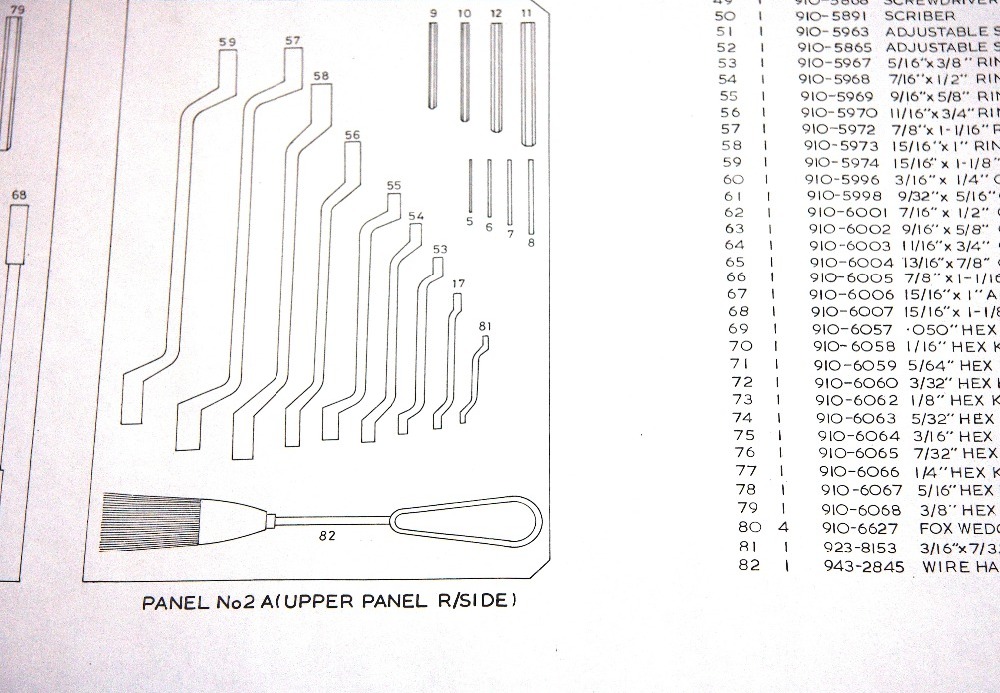

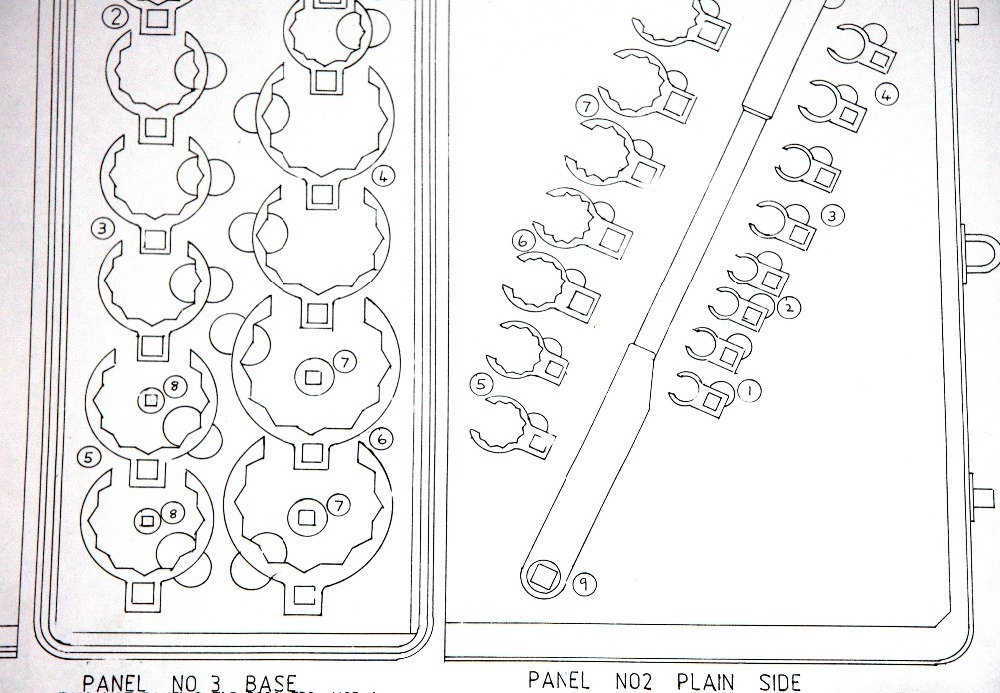

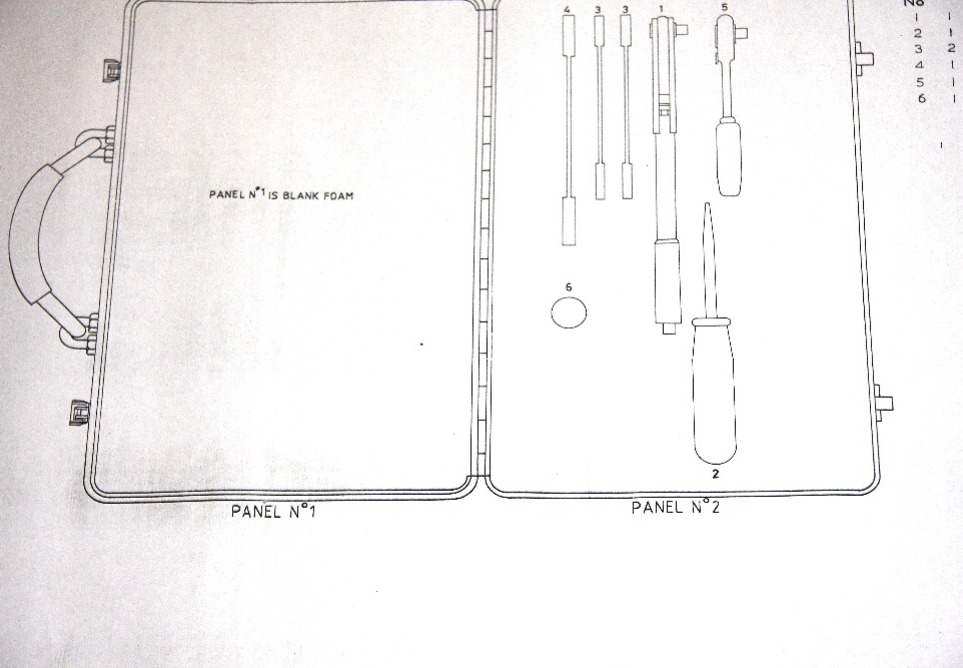

All are contained in a G.R.P box. The panels which hold the tools are developed to contain a specific tool complement as required for designated work. Every tool layout is comprehensively documented by means of Tool layout Design drawings; these drawings show full details of the box, its function , tool compliment and panel layouts, and are numbered for for identification and reference purposes.

Advantages which accrue from use of such a Tool Control System need hardly be stressed: some of the obvious ones are, briefly:-

ECONOMY/EFFICIENCY

Ease of tool identification and selection, ease of access, handling and checking, increase operative efficiency, and result in important work time reduction in all stages of use. With effective but simple control, the high cost normally arising from day to day tool losses is reduced to a minimum, and the consequent savings over a period are significant. Additionally, the cove afforded by a tailored system greatly reduces the number of kits required, and therefore substantially reduces the capitol cost of furbishing and re-furbishing.

DURABILITY

Fibre glass containers have the double advantage of high strength combined with lightness in weight: the boxes will stand up to very long and wear, in all conditions and climates. repair, when necessary, can be carried out simply effectively and relatively cheaply.

FLEXIBILITY

Box records/documentation make it possible not only for complete boxes/units to be re-ordered by reference to the identification numbers which relate, but also for revisions to layouts, and modifications to retention features, to be specified for separate supply, thus retaining boxes in service, with ultimately little withdrawal costs.

When ordering a replacement panel it is only necessary to quote the relevant TLD No and panel No. the replacement of a defective panel by a new panel involves, at the most, removal and replacement of 5 set screws.

SAFETY

Tool retention features are so designed that whilst tools can easily extracted and replaced, they are securely held when in position, and every tool position is clearly identifiable by its silhouette. the Tool kit verification is simplified, and the likelihood of tools being left in or around related equipment is thus minimised: a factor on no little value, particularly when high cost equipment is involved.

36 Piece Beryllium Copper Non Mag EOD kit

85 Piece Beryllium Copper

Non Mag EOD Kit

Non Magnetic Toolkit

A recent project to refurbish on board tool kits on 3 Corvettes

Toolkit Drawings

FIND OUT MORE

Below is a list of RATS tool kits we have previously supplied

|

Tool kit No |

Tool Kit No |

Tool Kit No |

Tool Kit No |

|

BDR |

E18 |

S1 |

W7M |

|

DC |

E18A |

TIC |

W08 |

|

DCBA |

E18B |

TIC2 |

W8 |

|

E1 |

E19 |

TIC LOOSE |

W8A |

|

E2A |

E19B |

T3 |

W9 |

|

E2B |

E19C |

T03 |

W9A |

|

E3A |

E19D |

T03M |

W10 |

|

E3B |

E19DM |

T4 |

W10A |

|

E4 |

E19M |

T6 |

W11 |

|

E4A |

E19S |

T06 |

W12 |

|

E5A |

E20 |

TIC2 |

W12A |

|

E5B |

E21 |

W1 |

W13 |

|

E5C |

E22 |

W1B |

W14 |

|

E05CE |

E23 |

W02 |

W15 |

|

E5E |

E24 |

W2 |

W16 |

|

E6 |

E25 |

W03A |

W17 |

|

E7 |

E29 |

W3A |

W24 |

|

E8 |

E29M |

W04 |

W24M |

|

E9 |

E32 |

W4 |

W25A |

|

E10 |

E36 |

W05/08 |

W25B |

|

E11 |

E39 |

W5 |

W26 |

|

E12 |

GTCU1 |

W5A |

W27 |

|

E13 |

GTCU2 |

W5M |

W28 |

|

E14 |

GTCU3 |

W06/07 |

W29 |

|

E15 |

GTCU4 |

W6 |

X1 |

|

E15M |

GTCU5 |

W6A |

X02 |

|

E16 |

M01 |

W6M |

X2 |

|

E16A |

M1 |

W7 |

X4 |

|

E17 |

M4 |

W7A |

XB |